How to choose?

___________________

一、The importance of fan selection in ventilation engineering

1、The concept of ventilation engineering

As an important part of the construction field, ventilation engineering aims to realize the optimization and adjustment of the indoor environment through reasonable air flow design. Its basic concept is to introduce the outdoor fresh air into the room through the ventilation equipment and system, and discharge the indoor dirty air, so as to maintain the fresh and comfortable indoor air. The function of ventilation engineering is not only to provide the necessary air exchange, but also to achieve the multiple goals of energy saving, environmental protection and health through the precise control of air flow.

In practical application, the effect of ventilation engineering is often closely related to factors such as building type, use function and regional climate. For example, in large commercial complexes, ventilation projects need to meet the air exchange needs caused by a large number of people, including issues such as energy saving and noise control.

2、The role and status of the fan

Fan plays a vital role in ventilation engineering, and its position is irreplaceable. As the core component of the ventilation system, the fan is responsible for introducing fresh air into the room, while discharging the dirty air to ensure that the indoor air quality meets the standard. In large buildings such as shopping malls, hospitals, factories and other places, the fan is an important task of maintaining the comfort of the environment and ensuring the health of personnel.

The position of the fan in the ventilation engineering is also reflected in its energy saving and consumption reduction. With the improvement of environmental awareness and the rise of energy costs, more and more ventilation projects begin to pay attention to the energy efficiency ratio and energy saving performance of fans. By adopting advanced control technology and optimized design scheme, the operating efficiency of the fan has been significantly improved, while the energy consumption and operating costs have also been reduced.

The role and status of the fan in the ventilation engineering can not be ignored. It is not only the key equipment to ensure indoor air quality, but also an important means to achieve energy saving and consumption reduction and improve environmental comfort. Therefore, in the design and implementation process of ventilation engineering, the selection, configuration and operation management of the fan should be fully considered to ensure that the overall performance and effect of the ventilation system reach the best state.

3、The influence of the fan selection on the ventilation effect

The selection of fan is very important to the ventilation effect, which is directly related to the overall performance of ventilation engineering. Taking a large commercial complex as an example, its ventilation system adopts high efficiency centrifugal fan, which ensures the uniformity and stability of air circulation by accurate calculation of parameters such as air volume and air pressure.

The selection of the fan not only affects the ventilation effect, but also is directly related to the energy consumption and the operating cost. Research shows that efficient fans can reduce energy consumption by more than 20%, thus saving a lot of operating costs for enterprises. At the same time, the high efficiency fan can also reduce noise and vibration, improve the quality of the working environment.

___________________

二、Type and selection of the fan

1、centrifugal fan

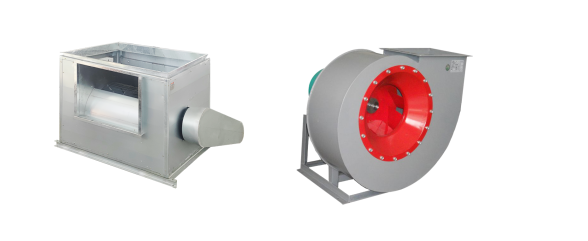

Figure 1 [left] cabinet type centrifugal fan / [right] centrifugal ventilation fan

Centrifugal fan plays an important role in ventilation engineering. Its working principle is based on the action of centrifugal force, through the rotating impeller to inhale and accelerate the air, and then the high-speed airflow to the outlet, to achieve the effective delivery of air. This fan has the characteristics of large air volume and stable wind pressure, and is suitable for large ventilation systems and places requiring high wind pressure.

Centrifugal fan also has the advantages of low noise and convenient maintenance. Its compact structure, reasonable design, make the noise level is effectively controlled, to provide users with a more comfortable environment. At the same time, the maintenance of centrifugal fan is relatively simple, only regular cleaning and inspection, to ensure its long-term stable operation.

To sum up, the centrifugal fan plays an important role in ventilation engineering with its characteristics of high efficiency, low noise and convenient maintenance.

2、 fanAxial flow fan

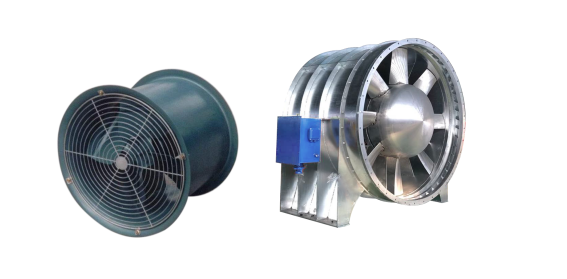

Figure 2 [Left] ventilation axial flow fan / [right] Subway tunnel axial flow fan

Axial flow fan plays an important role in ventilation engineering. The main characteristic of this kind of fan is that the air flow flows along the axis direction, which has the advantages of high efficiency, low noise and stable operation. In practical application, axial flow fans are often used in large buildings, factory workshops and other places that need a lot of ventilation.

The performance advantage of the axial flow fan is also reflected in its high efficiency and energy saving. Compared with other types of fans, axial flow fans have lower energy consumption at the same air volume. This benefits from its unique blade design and airflow control mechanism that minimizes energy loss. In addition, the axial flow fan also has good adjustment performance, can adjust the air volume according to the actual demand, to achieve energy-saving operation.

When selecting axial flow fan in ventilation engineering, its characteristics and application scenarios should be fully considered. For example, in places where a large amount of ventilation is required, axial flow fans are preferred because of their high efficiency and low noise characteristics.

3、Mixed flow fan

Figure 3. Mixed-flow fan

Mixed-flow fan, as a ventilation equipment with the characteristics of both centrifugal and axial flow fan, plays an important role in ventilation engineering. Its characteristic is characterized by the combination of high wind pressure of centrifugal fan and the advantage of axial flow fan, so that the mixed-flow fan can show excellent performance in specific scenarios. Compared with the traditional centrifugal or axial flow fan, the mixed flow fan can provide greater air volume and higher wind pressure at the same power,

Another significant feature of the mixed-flow fan is its stable operation and low noise. Because to the advanced hydrodynamic design and manufacturing process, it can maintain a low noise level during operation. At the same time, its compact structure and convenient installation characteristics also make the mixed-flow fan is widely used in ventilation engineering.

In addition, the mixed-flow type fan also has the advantage of high efficiency and energy saving. By optimizing the design and manufacturing process, the mixed-flow fan can reduce the energy consumption while ensuring the performance. In practical applications, mixed-flow fans can often save more energy than traditional fans, thus reducing the operating cost.

Mixed-flow fan plays an important role in ventilation engineering with its unique characteristics and advantages. Through the reasonable selection and application of the mixed-flow fan, it can effectively improve the performance and the efficiency of the ventilation system, to create a more comfortable and healthy indoor environment to provide a strong guarantee.

___________________

三、Fan parameters and material selection

1、Key parameters such as air volume and air pressure and power

In ventilation engineering, the selection of fan is very important, among which the key parameters such as air volume, wind pressure and power are the important basis for evaluating the performance of fan. Air volume, that is, the air volume through the fan per unit time, directly determines the ventilation effect. For example, in the ventilation system of large commercial buildings, in order to meet the indoor air quality requirements, fans with high volume need to be selected to ensure adequate air circulation. The wind pressure reflects the ability of the fan to overcome the pipeline resistance and transport the air. In high-rise buildings or long-distance ventilation pipes, wind pressure requirements are often high to ensure that air can be transported smoothly transported to the target area. Power is the power consumption required by the fan operation, which is directly related to the operation cost. When selecting the fan, the relationship between the air volume, wind pressure and power should be considered comprehensively to achieve the best performance and economic benefits.

Taking the hospital ventilation engineering as an example, because the hospital has high requirements for indoor air quality and the ventilation pipe is long, it pays special attention to the parameters of air volume and wind pressure when choosing the fan. After comparative analysis, a fan with high air volume and high wind pressure was finally selected to ensure the circulation and fresh air inside the hospital. At the same time, by optimizing the power configuration of the fan, the operating cost is reduced, and the win-win situation of economic benefits and environmental benefits is achieved. In addition, in the process of fan selection, a professional analysis model or software can also be used to simulate and predict the performance of the fan, so as to more accurately evaluate whether it meets the engineering needs.

In the ventilation project, the selection of key parameters such as air volume, air pressure and power is not only related to the quality of the ventilation effect, but also directly affects the operation cost and economic benefits of the project. Therefore, in the process of fan selection, various factors need to be comprehensively considered to ensure that the selected fan can meet the needs of the project and achieve the best ventilation effect.

2、Fan efficiency and energy consumption assessment

In the ventilation engineering, the fan efficiency and energy consumption assessment are the key links in the selection process. The efficiency of the fan directly determines its energy conversion ability, while the energy consumption is related to the operating cost and environmental impact. Therefore, in the selection of fans, its efficiency and energy consumption index must be fully considered.

Taking a ventilation project of a large commercial complex as an example, the project adopts a centrifugal fan with high efficiency and low energy consumption when used in the selection of the fan. By comparing the efficiency curve and energy consumption data of different types of fans, the fan with an efficiency of more than 85% is finally selected. In the actual operation process, the fan not only meets the ventilation requirements, but also significantly reduces the energy consumption, and saves a lot of operation costs for the commercial complex.

In the evaluation of the fan efficiency and energy consumption, in addition to the inherent performance of the fan, a comprehensive analysis should be combined with the actual needs of the project. For example, in areas with large air volume demand, fans with slightly larger capacity can be selected to ensure ventilation effect, while in areas with small air volume demand, fans with moderate capacity can be selected to avoid excessive energy consumption. In addition, the installation location, layout optimization, operation and maintenance factors of the fan will also affect the efficiency and energy consumption.

In order to improve the efficiency of the fan and reduce the energy consumption, the advanced control technology and the intelligent management means can also be adopted. For example, by adjusting the fan speed by the inverter, the air volume can be adjusted according to the actual demand to realize energy-saving operation; meanwhile, the real-time monitoring and remote control with the Internet of Things technology, which can find and solve the problems in operation in time and improve the stability and reliability of the fan operation.

In conclusion, the evaluation of fan efficiency and energy consumption is important in the selection of ventilation engineering fans. By comprehensively considering the performance parameters, engineering requirements and operation and maintenance factors of the fan, the fan can meet the ventilation demand and have the characteristics of high efficiency and low energy consumption, and provide a strong guarantee for the smooth implementation and long-term stable operation of ventilation engineering.

3、Noise and vibration control requirements

In ventilation engineering, the noise and vibration control requirements are critical to the selection of fans. Noise not only affects the living and working environment, but also may negatively affect people's physical and mental health. Therefore, the noise level of the fan must be fully considered when selecting it. For example, when a large factory upgraded its ventilation system, it chose a low-noise design fan, which reduced the noise level in the working area by nearly 20 decibels and significantly improved the working environment of employees. At the same time, vibration is also a factor that cannot be ignored in the selection of fan. Excessive vibration not only affects the stable operation of the fan, but also may cause damage to the equipment. Therefore, when selecting the fan, it needs to pay attention to its vibration control performance. Some advanced fan products adopt advanced vibration suppression technology, such as active vibration control, which effectively reduces the vibration level and improves the stability and reliability of the equipment.

In addition to considering the noise and vibration performance of the fan itself, it also needs to be selected according to the specific needs of ventilation engineering. For example, for high static pressure and gale volume, centrifugal fan with high noise reduction and vibration reduction design can be selected, and axial flow fan with low noise and low vibration can be selected. In addition, for places where noise and vibration control requirements are particularly strict, the use of muffler, shock absorber and other auxiliary equipment to further reduce the noise and vibration level.

In the process of fan selection, it is also necessary to pay attention to the interpretation and application of the fan performance curve. The performance curve can directly reflect the noise and vibration level of the fan under different working conditions. By comparing the performance curves of different types of fans, the best fan that meets the requirements of noise and vibration control can be selected. At the same time, it can also predict the noise and vibration of the fan in the actual operation according to the performance curve, providing an important reference for the subsequent debugging, operation and maintenance.

In conclusion, noise and vibration control requirements are important considerations in the selection of fan in ventilation engineering. By selecting the fan with excellent noise and vibration control performance, selecting the engineering requirements, and rationally applying the fan performance curve, it can effectively reduce the noise and vibration level of the ventilation system, improve the quality of the working environment, and ensure the stable operation of the equipment.

4、Fan material and anti-corrosion requirements

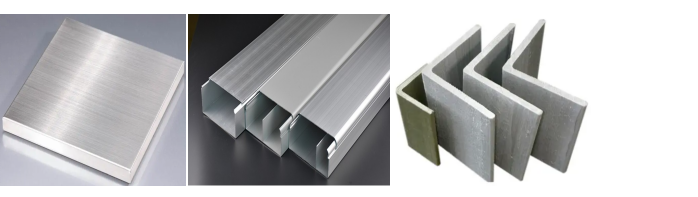

Figure 4 [Left] Stainless steel material / [middle] aluminum alloy material / [right] FRP material

In ventilation engineering, the selection of fan material is directly related to its anti-corrosion performance and service life. Common fan materials include stainless steel, aluminum alloy, FRP, etc.

Stainless steel fan because of its excellent corrosion resistance, in the humid, corrosive strong environment excellent performance, such as chemical, electroplating and other industries ventilation system.

Aluminum alloy fan is favored for its light weight, high strength and good thermal conductivity, suitable for the weight and heat dissipation performance requirements.

FRP fan is widely used in outdoor or in harsh environment.

In the selection of the fan material, in addition to considering its anti-corrosion performance, but also need to comprehensively consider the cost, processing difficulty, maintenance convenience and other factors. For example, although stainless steel fan, the cost is relatively high, but the strength and wear resistance may not be better than that of stainless steel fan. Therefore, in the practical application, it is necessary to weigh and choose according to the specific engineering needs and the budget.

In addition, in order to improve the corrosion resistance of the fan, some additional corrosion prevention measures can be taken. For example, the surface of the fan is sprayed to form a protective film to isolate the erosion of air and moisture on the fan material. At the same time, regular maintenance and maintenance of the fan, timely cleaning of dust and dirt, to keep its surface clean and dry, is also an effective means to extend the service life of the fan.

To sum up, the fan material and anti-corrosion requirements are the important links that can not be ignored in the ventilation engineering. By reasonable selection of the fan material and effective anti-corrosion measures, it can ensure the stable operation of the fan in the harsh environment and provide reliable power support for ventilation engineering.